SCOPE

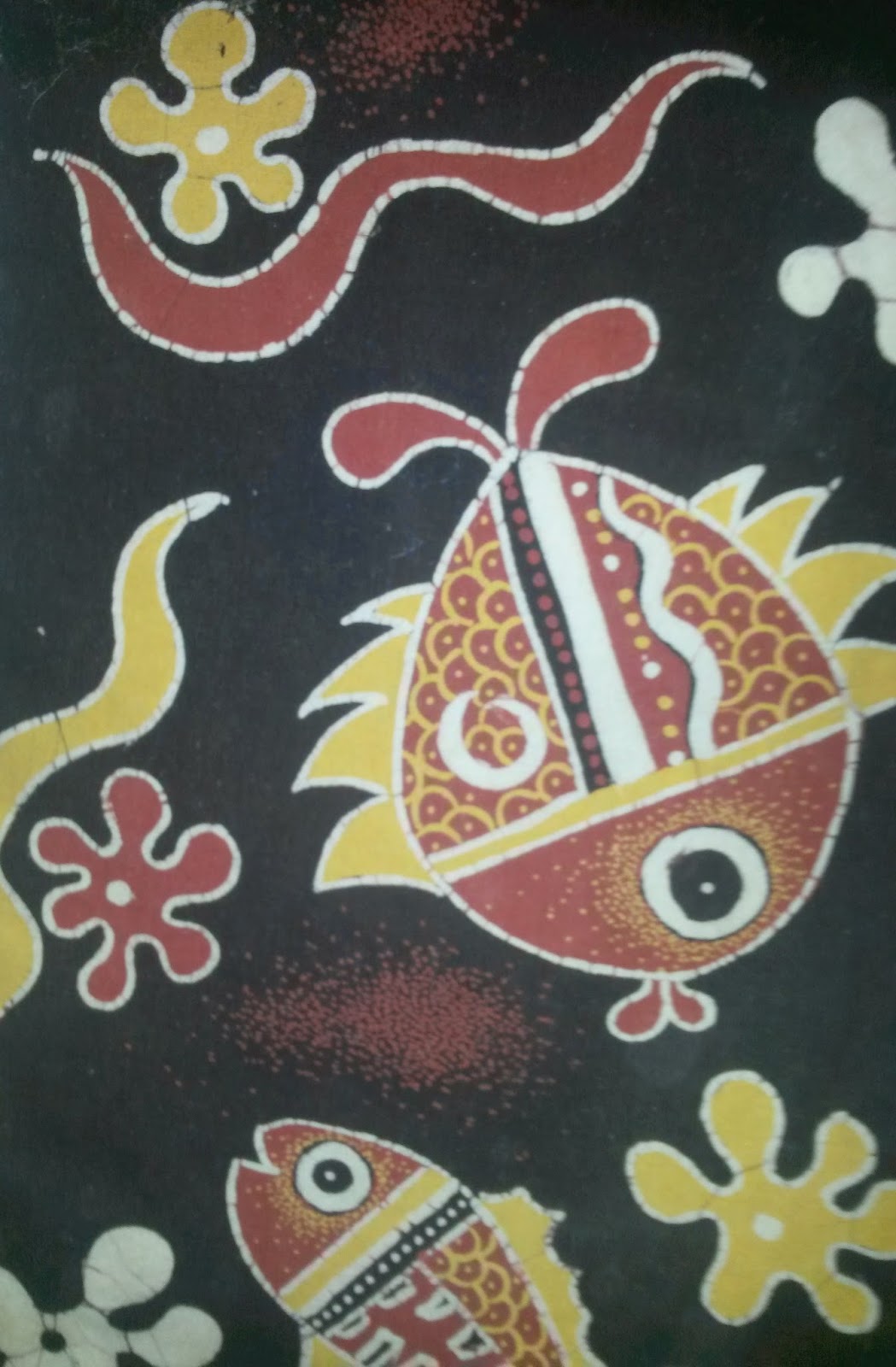

This standard prescribes recommended raw materials and a set of

procedure for the manufacture of cloth according to the batik dyeing

process. It also gives and product

requirements and methods of test for batik cloth.

TERMINOLOGY

(1) “Tjap” - specially made block composed of copper

strips hand worked and frilled into a

copper lattice and held in place by solder. Printing on both sides is possible using this

equipment and a high degree of precession even in intricate designs may be

obtained.

(2) “djanting” - a

small cup made of thin copper sheet which carries a tabular spout at one

end and fitted into a short bamboo rod at the other

by means of a rolled extension of copper sheet which with of the line it is

desired to trace.

(3) Paraffin wax - A higher homologues of paraffin obtained as a

residue from the

distillation of petroleum. Melting point 450C to 650C. specific gravity 0.9

(4) Bee’s wax -

A white or yellow plastic

substance obtained from honey comb of the bee.

Melting point 630C to 650C. It consists chic fly of nyrichyl ester of

palmitic acid , C15, H31,

COO, C30, H16, free cerotic

acid C25, H51, COOH and other homologues.

(1)

Vat dyes – A series of insoluble dye stuffs that can be reduced to

their water soluble leuca compounds , which are oxidi8xsed by exposure to the

air, thus producing the dye

stuff direct on the fibre.

(2)

Reactive dyes - Classes of dye

stuffer which react chemically with textile fibers. Many dyes of this type are based on cyan uric

chloride and the chemical linkage between dye & fibre depends on a tria

zinic nucleus.

RAW MATERIAL REQUIREMENTS

Base material

Recommended base materials - The

following types of base materials are recommended.

|

ITEM

|

RECOMMENDED

ASE MATERIALS

|

|

Shirts

|

Poplin

|

|

Sarees

|

Voile, Silk

|

|

Scarves

|

Voile, Silk

|

|

Wall hangings

|

Any suitable cotton materials

|

|

Dress lengths

|

Poplin

|

|

Cushion covers

|

Poplin, sheeting

|

|

Ties

|

Suitable silk and cotton

|

|

Table cloths

|

Sheeting

|

|

Bed spreads

|

|

Hankerchiefs

|

Voile, Silk

|

A close weave cloth takes in fine details in design the wax percentages

completely through the cloth.

STRINKAGE - base material used for batik printing shall

have a maximum shrinkage of 4%.

The requirements should be taken with extra measurement added to the

basic measurements due to the shrinkage and if the cloth would wash there will

be no need of taking extra measurements.

Scouring loss _ Base material used for batik printing shall

have a maximum scouring loss of 2.5%.

Wax :- A mixture of paraffin wax & bees wax is recommended for covering

the clothe prior to

dyeing.

Dyes :- The following types of

cold water dyes are recommended

(a) Indigo and other cold dying vat dye stuffs.

(b) Azoic dye stuffs.

(c) Reactive cold dye may be used.

Identifying cotton material

By doing burning test : It would be easier. If you get grayish ash and a poplin burning

smell; while burning will be pure cotton

material and if the material melts that means it contain synthetic material.

Packaging

Packages ; each pieces shall be folded or wrapped on

cardboard or straw board of suitable size and thickness. Each piece or bundle of pieces shall be

wrapped in suitable packaging materials which do not adversely affect the

cloth, & which will not stain the cellophane or polythene film.

Bulk containers ;- packages

obtained as in clause may be packed in suitable containers. Only items of the same type (eg. shirts,

hangings) may be packed together in a bulk container.

LEBELLING

Packages : The following information shall appear in legible and in

illegible marking on a label securely attached to each package.

(a) Manufactures

name & / or trade mark .

(b) The words “Hand waxed & dyed by genuine batik

wax resist process.

(c) Contents of package.

(d) Washing & cleaning instructions.

(e) Country of origin.

THE BASIC COMPARTMENTS OF A BATIK FACTORY

(1)

Drawing

(2)

Tracing

(3)

Working

(4)

Dyeing

(5)

Storing

(6)

Chemicals

(7)

Boiling

(8)

Washing

(9)

Ironing

( 10) Storing